Wesman Compact mini sand preparation plant is designed to cater to small foundries for manual operation and consists of a package of screening of lumps and iron particles, charging to mixer, mixing and aeration systems for foundry return sand.

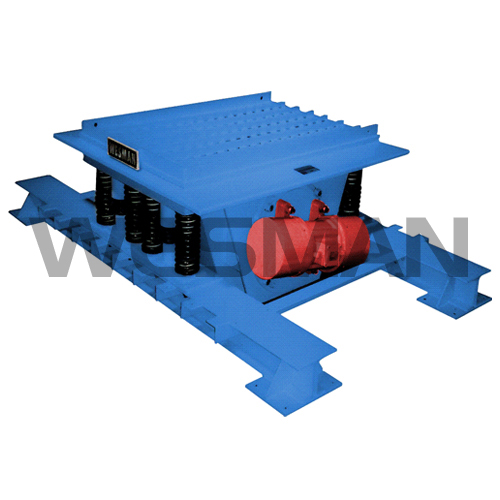

READ MOREDesign for continuous duty to separate castings from mould, sand from flasks and cores from casting . It consists of of a drilled top deck, floating on heavy–duty springs resting on supporting structure. Top frame is shaken violently either by eccentric shaft drive mechanism or by vibromotor.

READ MORE

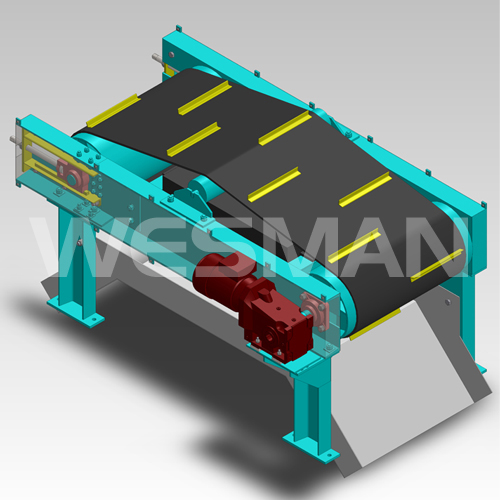

Utilize to convey sand or granular particles and placed under shake out or use as a grid to eliminate direct handling of hot sand by belt conveyor. It features with low wear rate of trough, special oscillating pattern for efficient conveying and designed to continues-duty feeding to downstream equipment.

READ MOREWesman Overband Magnetic Separator is used for efficient removal of ferromagnetic particles from sand. It is virtually a static suspension of a permanent magnet, suitably placed between the top and bottom belt of a small belt conveyor.

READ MORE

Wesman Rotary Polygon Screens are used in Sand Conditioning Plants for removal of hard lumps of sand, large pieces of scrap, non-magnetic and coarse foreign materials from the knocked out used sand.

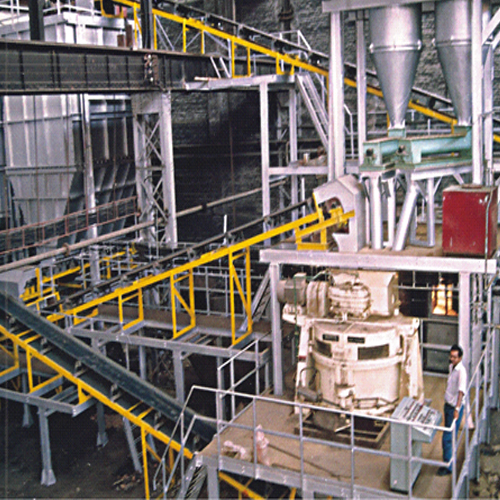

READ MOREWesman Sand Preparation / conditioning plant can give the best return of the investment offering the most energy efficient sand system designed to provide the optimized solution to produce best quality molding sand. It is the product of Wesman’s long years of experience combined with the cutting edge technology of its global partners. Wesman can offer complete range of green sand equipment consisting of vibratory Shakeout Machine, Oscillating Trough Conveyer, Belt Conveyer, Over band Magnetic Separator, Bucket Elevator, Polygonal Screen, Return Sand Cooler, Bunkers, Feeders, Mixer / Muller, Mixed sand distribution system and complete automation.

READ MORE