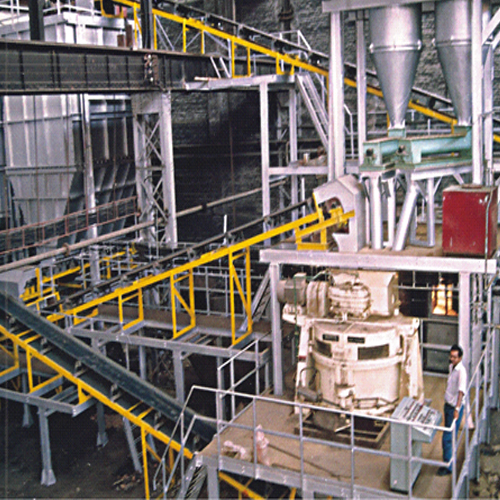

Wesman Sand Preparation / conditioning plant can give the best return of the investment offering the most energy efficient sand system designed to provide the optimized solution to produce best quality molding sand. It is the product of Wesman’s long years of experience combined with the cutting edge technology of its global partners.

Sand molds are shaken out by shakeout machine to separate the castings from the molding sand. Used sand is transferred by metallic conveyor followed by belt conveyor to bucket elevator. The overband Magnetic separator and the magnetic pulley segregate the magnetic particles from the return sand. Hexagonal sieve breaks the lumps and screen it to original sand grain. For efficient cooling of the return sand we use SIMPSON Multicooler which is globally acclaimed as the best green sand cooler, which not only cool down the sand most efficiently, but pre-mix the sand and maintain the moisture level at constant level (preferably @2% with +/- 0.2% variation) for better utilization of bentonite. Finally >95% foundry sand is reclaimed to sand hopper reservoir for recycling.

Wesman Sand plant is divided into three major group. Return sand group, where equipments are:- Shakeout, Metal trough oscillating conveyor, Belt conveyor, Bucket elevator, Magnetic separator, Polygon screen, Storage hopper, Reversible belt feeder, Multicooler, Bucket elevator and Storage hopper.

Sand preparation group:- Sand Muller / Intensive mixer / Rotomix / Speed muller, Screw feeder, Belt feeder,

Prepared sand group:- Belt conveyor, Online aerator, Distribution belt with “V” plough and Molding hoppers.

All the groups are integrated with specially design latest PLC panel with HMI having optional data lodging system.

REQUEST A QUOTE