The Cokeless Melting Furnace uses Natural Gas, Propane, LPG or Coal Bed Methane (CBM) which has similar composition and calorific value as that of Natural Gas. Even Light Oil may be used provided there is no Sulphur in the oil. Absence of sulphur makes the molten metal obtained from Cokeless Melting furnace suitable for conversion, after superheating, into Ductile Iron without going through the de-sulphurision process where temperature is reduced due to endothermic reaction. Thus further heating / addition of heat energy to compensate the temperature loss is avoided by using the Ecomelt furnace.

In India this Cokeless Melting Technology has a special significance. Elimination of coke is a great relief to the foundry men as availability of coke is erratic and the price is highly fluctuating. Also, considering the shortage of power in India, it may be noted that when duplexed with Induction Furnace for production of Ductile Iron, the  power requirement is reduced substantially. Both Cokeless Melting Furnace and the Induction furnace may be run by a standby generator of reasonably low rating. The duplexing with Induction furnace also results in lowest over all melting cost which provides the foundry a cutting edge in the competitive market.

power requirement is reduced substantially. Both Cokeless Melting Furnace and the Induction furnace may be run by a standby generator of reasonably low rating. The duplexing with Induction furnace also results in lowest over all melting cost which provides the foundry a cutting edge in the competitive market.

Besides achieving lowest melting cost, the pollution norm of the country can easily be met without installing any pollution control device. If insisted by the authority, a simple low cost wet cap may be installed to further reduce the emission level. The SPM level, as measured in actual installations, is less than one third the allowable limits.

Because of high fuel efficiency of Cokeless Melting Furnace, much less fuel is consumed for melting same quantity of metal compared to that in other melting furnaces. As a result, for same quantity of molten metal, much less CO2 is emitted. Therefore, this technology qualifies as “Low Carbon” Green technology. As the name suggests these Cokeless Melting Furnaces are both Eco-friendly and Economical.

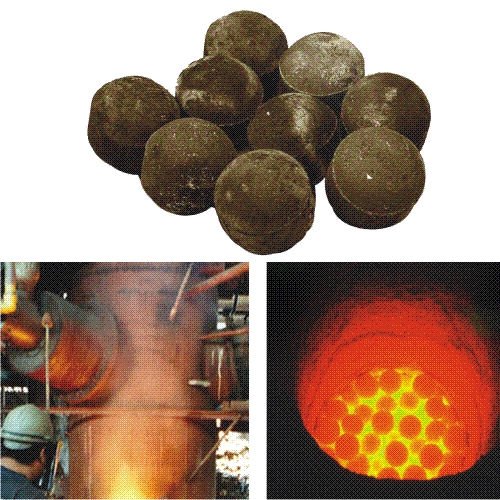

Wesman has set up a plant to manufacture the refractory spheres in Dankuni, West Bengal. The plant has been equipped with mixers, pressses, ovens and testing equipment to manufacture the ceramic bed material for the Ecomelt Cokeless Melting furnace.

Wesman has set up a plant to manufacture the refractory spheres in Dankuni, West Bengal. The plant has been equipped with mixers, pressses, ovens and testing equipment to manufacture the ceramic bed material for the Ecomelt Cokeless Melting furnace.

Foundries need ceramic spheres or balls as a consumable and Wesman's mission is to ensure that all foundries adopting the cokeless melting route have regular and constant supply of this essential input.

The spheres produced in this plant has been tested in a UK lab for confirming that the ceramic sphere produced in India conforms in all respects to the original spheres produced in the UK. Indian and overseas foundries have used the Wesman spheres since 2007 and have confirmed excellent results from the cokeless melting process

The spheres produced in this plant has been tested in a UK lab for confirming that the ceramic sphere produced in India conforms in all respects to the original spheres produced in the UK. Indian and overseas foundries have used the Wesman spheres since 2007 and have confirmed excellent results from the cokeless melting process