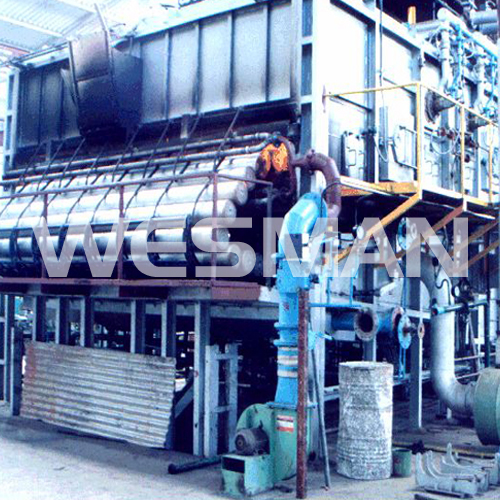

Wesman has a full range of batch type bogie hearth furnaces up to a capacity of 50 MT and continuous type walking beam furnaces up to a capacity of 10 MT per hour for homogenizing of aluminium extruded billets/logs and slabs.

Hot air recirculation inside the furnace is done by efficient axial or centrifugal type recirculation fan, which can be with two-speed motor or with VVF drive for low power consumption. Stainless steel baffle for proper hot air circulation inside the furnace is provided. Forced air-cooling arrangement with the help of centrifugal fan can be offered.

The furnaces are fired with Wesman’s high efficiency burners supported by a full complement of combustion system consisting of combustion fan, atomizing fan, oil heating and pumping systems and/or gas trains. In addition auto ignition, flame failure safety and complete control systems are offered. Practically any type of liquid or gaseous fuel can be used viz. Light Diesel Oil, LPG, Natural Gas singly or a combination of any oil or gas in case of dual fired furnaces.

As an alternate to fuel fired heating system, the furnace can be provided with electrical heating system through vertically suspended heater cartridges located along with the sidewalls of the furnace. The heating elements of the furnace are suitably divided into number of heating zones with each zone of having their bank of heater cartridges. Each bank heater cartridges shall be connected either in STAR/DELTA or Parallel STAR/DELTA groups to have minimum number of heater cartridges per phase per group so that the heater cartridges of groups can be isolated, without switching off the furnace in case they need replacement.

To improve the fuel efficiency, Recuperators for heating combustion air upto 200°C is provided for fuel fired continuous walking beam furnaces.

Wesman Homogenizing furnaces are lined with a combination of ceramic fibre board backed-up by ceramic fibre blankets of suitable grade with stainless steel studs for side wall, roof and doors to minimize the skin temperature. The hearth is lined with refractory bricks backed-up by insulation bricks, specially designed to withstand load. In an alternate design, the furnace can also be made of double wall construction with inner stainless steel (AISI-304) and outer mild steel for side wall, roof and doors in place of ceramic fibre board backed-up by ceramic fibre lining.

For electrically heated furnace, the process control shall be based on heat head ratio control philosophy with thyristor heater controllers for better temperature control and energy efficiency. Wesman’s electrically heated furnaces can be offered with 100% thyristor controllers or 30% thyristor with 70% STAR-OFF mode for better energy efficiency during heating & soaking.

REQUEST A QUOTE