Iron ore pellets are used to feed blast furnaces or DRI plants to make steel.

To make iron ore suitable for the above applications, Iron ore is processed into pellets and then fired in an indurating / travel grate furnace.

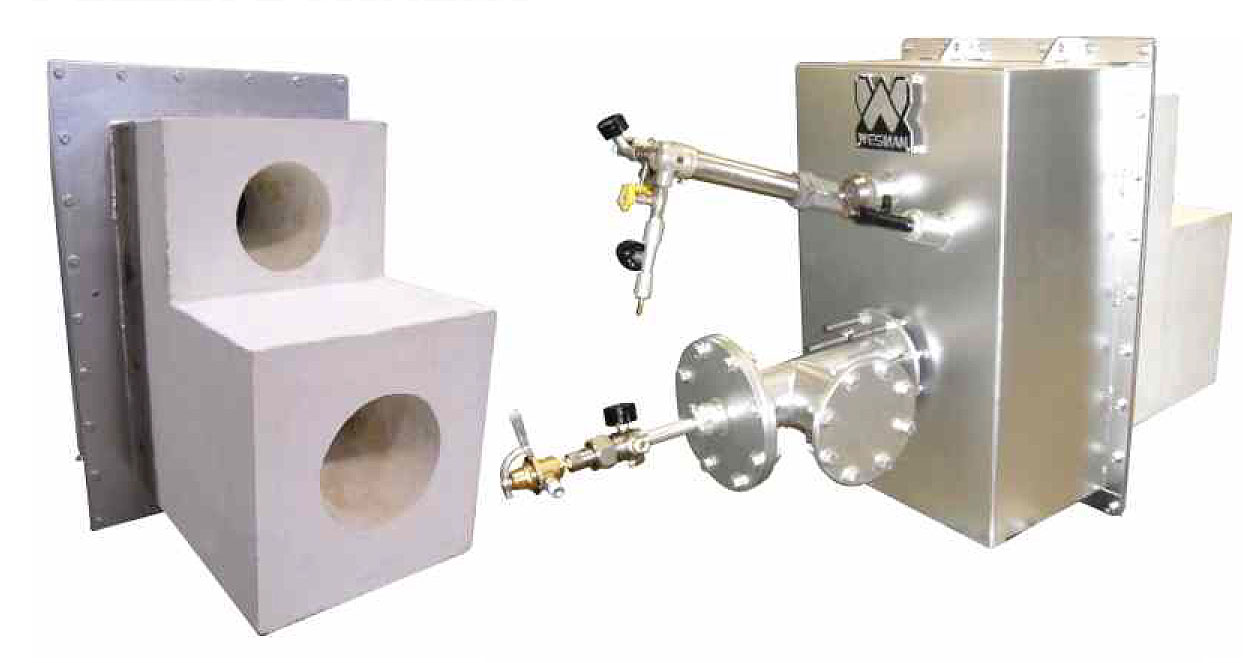

Wesman’s Pellet Burner series are installed on both sides of a travel grate / straight grate-indurating furnace to produce the required heat taking into consideration the heat produced within the furnace from the heated pellets. Our burners can handle a range of liquid fuels, which requires high pressure atomizing and gaseous fuel. The burner flame is compact and therefore reduces radiation heat reaching the pellets. Our Pellet Burners for Indurating furnace come in different sizes. Capacity ranging from 1 to 5 Mkcal/hr. For travel grate, we have different series Burners.

Our Pellet Burners can be fired using the following fuels (but not limited to):

We offer multiple options for operating the Pellet burners. We can integrate our burners to basic control systems with interconnected air and oil control valves. We also offer automated burner management systems with either relay or PLC based controllers. Flame detection systems with UV sensing or flame rods are also available.ForPilot Burners, we use LPG / NG / LNG.

Wesman supplies customized fuel-handlingskids for the pellet burners. A full range of valves, gauges and pressure switches along with associated fittings are supplied as part of our solution. For heavier oils, our fuel handling systems can incorporate the required heating systems, which include Loading / Unloading Skids, Pumping & Heating Unit, out flow heaters, Line heaters. For Light Oils, we use, loading / unloading unit, pumping unit. For gaseous fuel, we provide suitable gas train.

REQUEST A QUOTE